-

Upward Draft Bin Pump

Upward draft bin pump in powder pneumatic conveying system, the fluidising plate is at the bottom of the bin pump, the lower flaring tube of the material delivery pipe is installed at a suitable position above the fluidising plate, the upper end is straight up from the top of the bin pump, the booster jet is installed on the pipe at the outlet.

-

Downdraft Bin Pump

According to the direction of the discharge port, the bin pump is divided into downdraft bin pump, also known as bin pump, pneumatic conveying pump, sending tank, etc. The fluidising plate of the downdraft bin pump is in the lower part of the bin pump, and the fluidising plate is single or double plate. In order to enable the material to be discharged centrally, the conveying pipe is equipped with a conveying valve at the bottom of the bin pump. When the air pressure inside the bin pump reaches a predetermined pressure value, the conveying valve opens and the highly concentrated material flows into the conveying pipe for dense phase conveying.

-

Big Bag Emptying Station

Big Bag Emptying Systems is Bulk Bag Discharger for Emptying big bag materials. It is a Bag Emptying System for dry powder or small granular materials. It is mainly used in the fields of plastics, rubber, food, medical, minerals, chemical, building materials, grain, feed and so on.

-

Low Pressure Continuous Delivery Pump

This product is widely used in medium and short-range ash collection and transportation in power ash removal, building materials transportation, construction sites and other industries. It is an excellent product in solid conveying pumps. It is not limited by terrain and elevation difference, fully enclosed, pollution-free, simple structure and small maintenance. The air source is roots blower or compressed air.

-

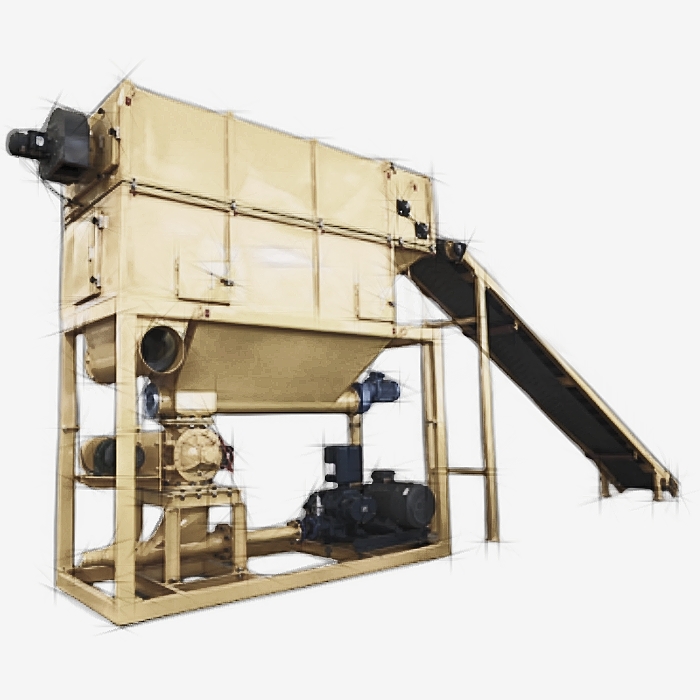

Cement Bag Emptying Station

Cement Bag Emptying Station is a highly efficient and environmentally friendly Cement Bag Breaker, which is capable of automatic Cement Bag Opener, automatically discharging the empty bags and conveying the cement to the cement silo using positive pressure pneumatic conveying. So, it improves the unloading efficiency and reduces the labor cost.

-

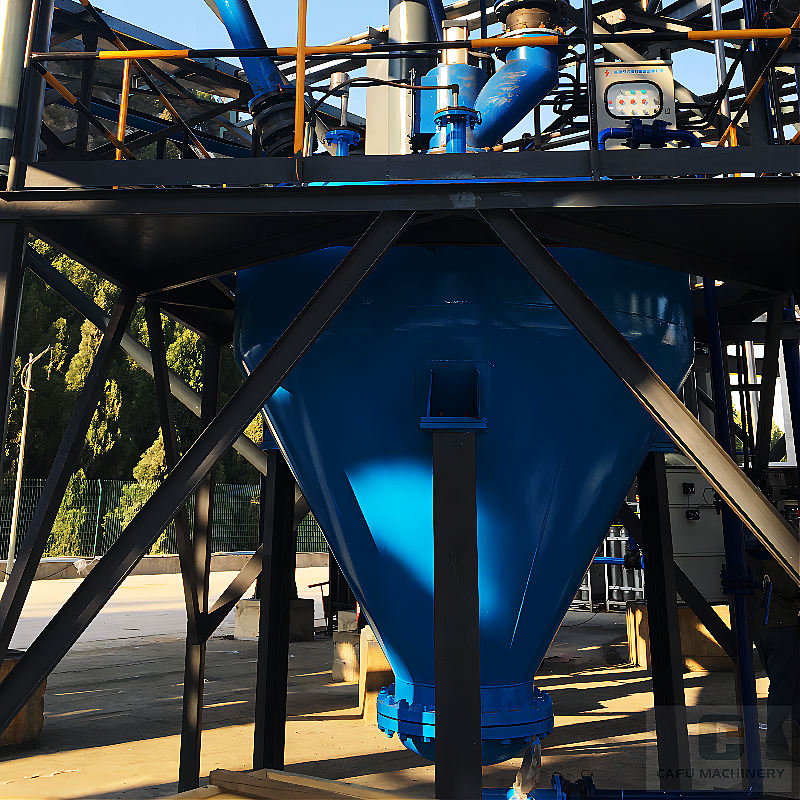

Double Silo Dense Phase Bin Pump

As a continuous powder conveying silo pump, has the characteristics of reliable technical level and advanced technology. The equipment is widely used in electric power, cement, food, metallurgy and other industries. The continuous delivery bin type pump sold by the company is composed of two pump bodies, which are controlled by the pipeline cutting valve to maintain the continuity of pipeline delivery. In many cases of powder pneumatic conveying system engineering, we maintain strong technical advancement and more practical experience. Principle introduction: in fact, it uses the principle of pneumatic pressure difference to transport. After the material enters the pump body, when it is filled with powder, the material forms a fluidization state after gasification. Through the mixing chamber, the compressed air is spewed out at high speed through the jet nozzle, and the fluidization powder is fully mixed evenly. Two warehouse type pumps can feed at the same time, feed in turn, transport materials alternately, pipeline can achieve uninterrupted transmission of powder, to meet the requirements of large throughput, is a reliable process for improving the capacity of powder pneumatic conveying system.

-

Pneumatic Grain Suction Machine

The pneumatic unloader is widely used in warehouses, terminals and processing plants for the transfer and loading and unloading of bulk granular materials, such as wheat, rice, soybeans, corn, rapeseed, feed, granular fertilizers, plastics and other materials, especially for the in and out of warehouses, transfer, loading and unloading of materials. As well as the local heat, high temperature, disease and insect mold operations on the surface of the grain bin.

-

Air Compressor

Our company matches cost-effective air compressors and air dryers for the pneumatic conveying system. Our company has been cooperating with China's mainstream air compressor manufacturers for a long time, using high-precision heads, and selecting high-quality motors and transmission systems. In outdoor working conditions, we also designed a moisture-proof enclosure with IP55 level and above, and designed abnormal protection devices, maintenance reminders, etc., suitable for long-term stable use in dusty working conditions. Considering the use of clean air, we have also prepared accessories such as automatic drains and air filters for use in pipeline installation.

-

Energy Saving Continuous Delivery Pump

The equipment has the characteristics of compact structure, flexible layout, low wind pressure, low energy consumption, easy operation, reliable operation and so on. It is a product with high performance in low-pressure continuous powder conveying equipment. Widely used in power plant fly ash pneumatic conveying system, power plant desulfurization limestone powder pneumatic conveying, cement kiln head, kiln tail powder pneumatic conveying. In the actual use, we have completely solved the other low pressure pump upward leakage gas, leakage lock is not tight.