- Home

- >

- Products

- >

- Bulk Material Conveying Equipment

- >

- Apron Feeder

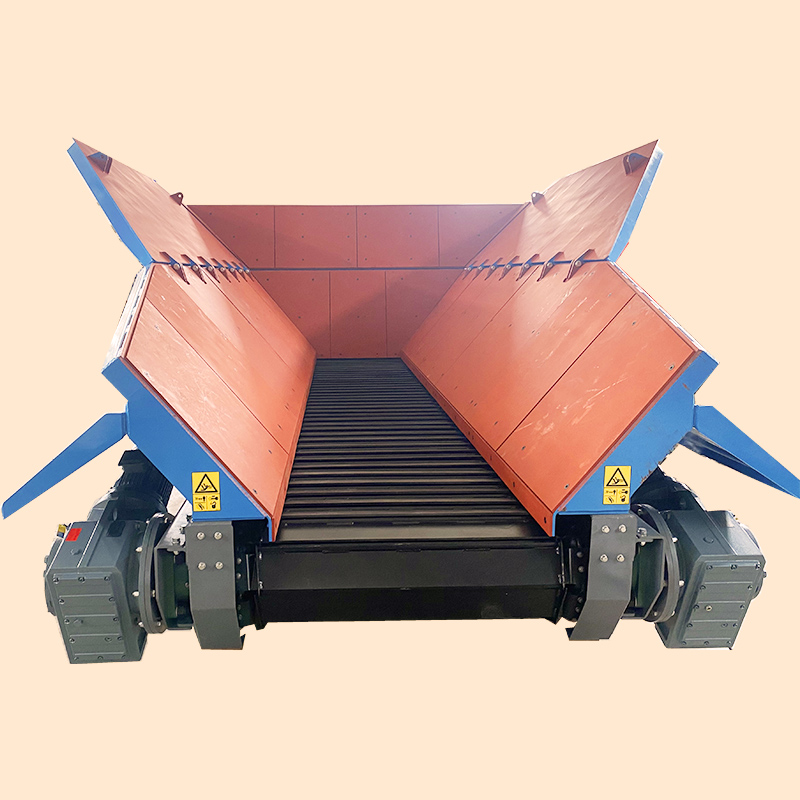

Apron Feeder

Brand :Cafu

Product origin :China

Apron Feeder are mainly used in production lines for quarries, aggregate processing, and large particle recycling applications.

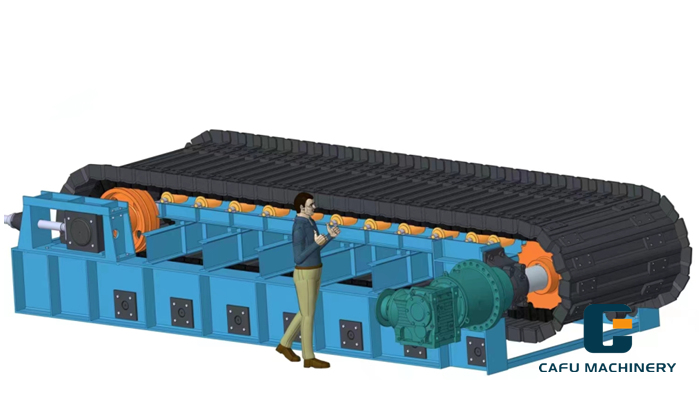

Apron Feeder is an important receiving and conveying device for heavy granular bulk materials. Due to the heavy-duty design of the apron feeder, it can withstand instantaneous discharge impact load, and is suitable for feeding large, massive, abrasive and heavy aggregates in humid, viscous or frozen operating environments, and is suitable for various occasions.

▍ Apron Feeder

● Design

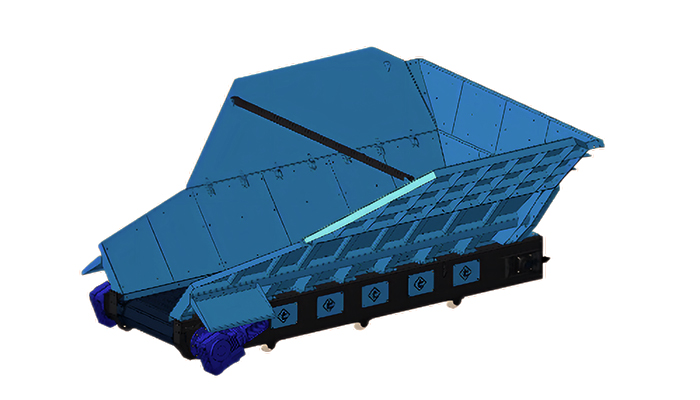

Apron feeder is designed with 3D modeling according to customer's requirements. And pre-assembled at the factory.

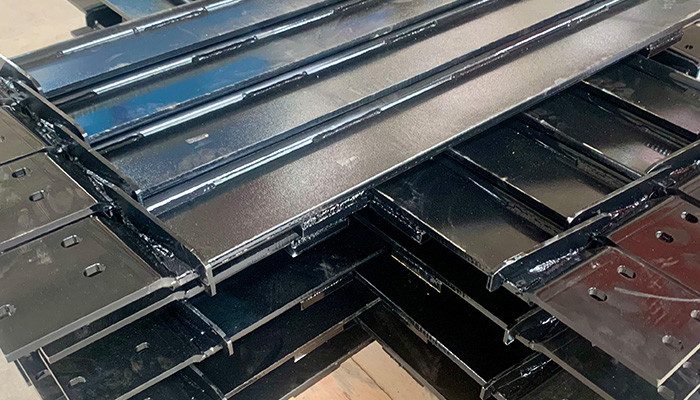

Design the chain plate of apron feeder according to different working conditions. The chain plates of all apron feeders are made of wear-resistant steel, which guarantees a long service life of the chain plates.

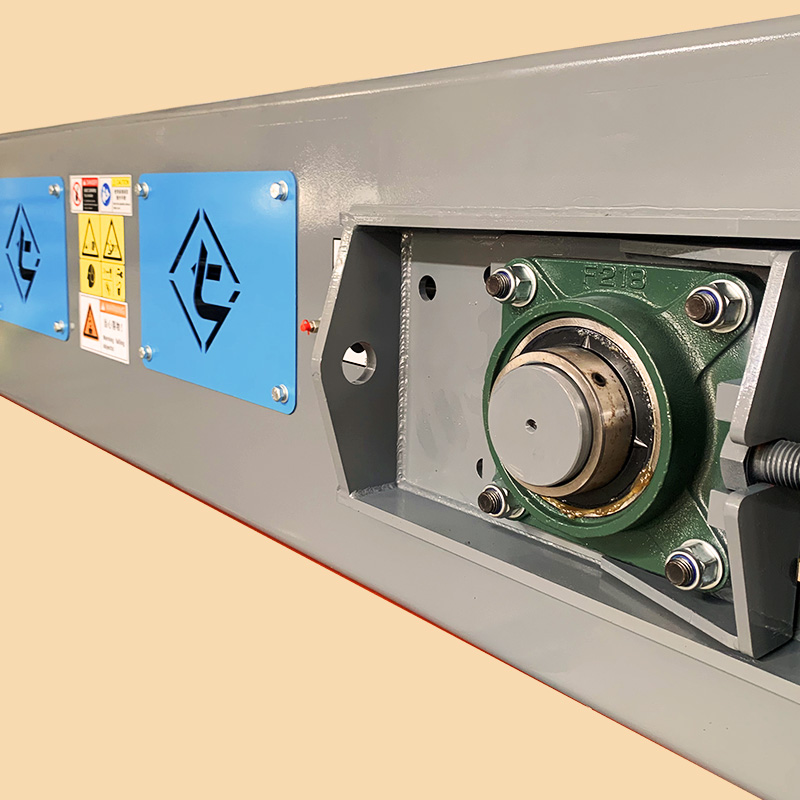

● Part selection

Excellent quality support wheels and chain components are selected to effectively prevent the entry of dust and sand, thus extending the service life of the combined parts.

● Assembly of parts & components

Strict installation process to ensure the stability of all moving parts.

● Shipping & Packaging

The assembled design ensures that all parts can be flexibly combined for packaging, and with good protection, the apron feeder can be easily loaded into containers.

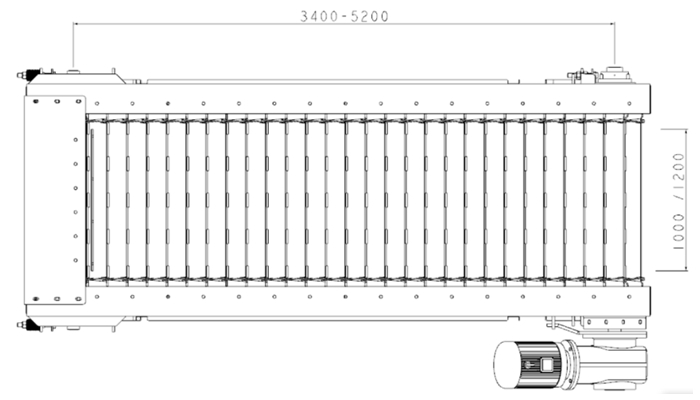

● Apron feeders Specifications(light duty)

| Model | Standard sizes(WxL,mm) | Power (kw) | Maximum feed size(mm) | Processing Capacity (THP) | Speed (m/s) | Angle (°) |

| LTF1034 | 1000x3400 | 11 | 500 | 250-400 | 0-0.3 | 0-20 |

| LTF1038 | 1000x3800 | 11 | 500 | 250-400 | ||

| LTF1043 | 1000x4300 | 15 | 500 | 250-400 | ||

| LTF1052 | 1000x5200 | 22(2x11) | 500 | 250-400 | ||

| LTF1234 | 1200x3400 | 15 | 600 | 250-500 | ||

| LTF1238 | 1200x3800 | 15 | 600 | 250-500 | ||

| LTF1243 | 1200x4300 | 22(2x11) | 600 | 250-500 | ||

| LTF1252 | 1200x5200 | 30(2x15) | 600 | 250-500 |

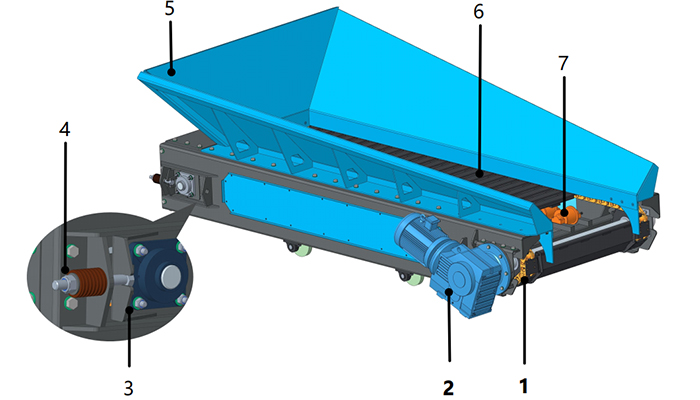

●The apron feeder has the following characteristics:

1、The use of crawler excavator chain reduces maintenance or is maintenance-free.

2、Use electric or hydraulic drive.

3、UCFX series heavy-duty bearings.

4、Tensioning by butterfly spring.

5、Customized type hopper, can be tailored according to customer requirements.

6、The wear-resistant chain plate is designed according to different working conditions.

7、Inner double-row drag chain wheel structure.

● Main application occasions of apron feeder:

Cement industry, iron ore, topsoil, bauxite, copper mine, coal mine, construction waste, limestone mine.

▍ Heavy Duty Apron Feeder Selection Instructions.

● Apron Feeder Technical Specifications(Heavy load)

| Model | Working width(mm) | Max. length(m) | Max. Feeding size(mm) | Capacity(m3/h) | Speed(m/s) |

| LTF800 | 800 | 15 | 340 | 60~350 | 0~0.3 |

| LTF1000 | 1000 | 18 | 460 | 100~500 | 0~0.3 |

| LTF1200 | 1200 | 20 | 600 | 110~580 | 0~0.2 |

| LTF1400 | 1400 | 20 | 650 | 130~800 | 0~0.2 |

| LTF1600 | 1600 | 20 | 700 | 300~1250 | 0~0.2 |

| LTF1800 | 1800 | 20 | 780 | 450~1550 | 0~0.15 |

| LTF2000 | 2000 | 20 | 950 | 500~1800 | 0~0.15 |

| LTF2400 | 2400 | 20 | 1400 | 500~2600 | 0~0.15 |

| LTF2800 | 2800 | 20 | 1700 | 900~3900 | 0~0.15 |

Please provide us with the following information on the use of the apron feeder:

1. Material to be processed: ______

2. Processing capacity: ______t/h

3. Material density: ______t/m³

4. Distance between the centre of the head sprocket and the tail sprocket: ______m

5. Is the layout of the apron feeder inclined or horizontal? If inclined, what is the inclination: ______°

6. Maximum particle size of the feed: ______mm

7. Percentage of maximum particles in the overall material: ______ %

8. What equipment is used to feed the material into the apron feeder: ______

9. What equipment is used to receive material from the apron feeder: ______

10. Working power supply:______V ______HZ

11. Quantity required: ______

12. Under normal conditions the equipment upstream of the apron feeder is the hopper. In order to facilitate our engineers to calculate the power of the apron feeder, can you provide a preliminary design of the hopper or a hand drawing sheet?

The apron feeder provided by CAFU will give you an excellent experience. For related technical parameters, please consult our engineers.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more