- Home

- >

- Products

- >

- Bolted Assembly Steel Silo System

- >

- Silo Bulk Material Weighing and Monitoring System

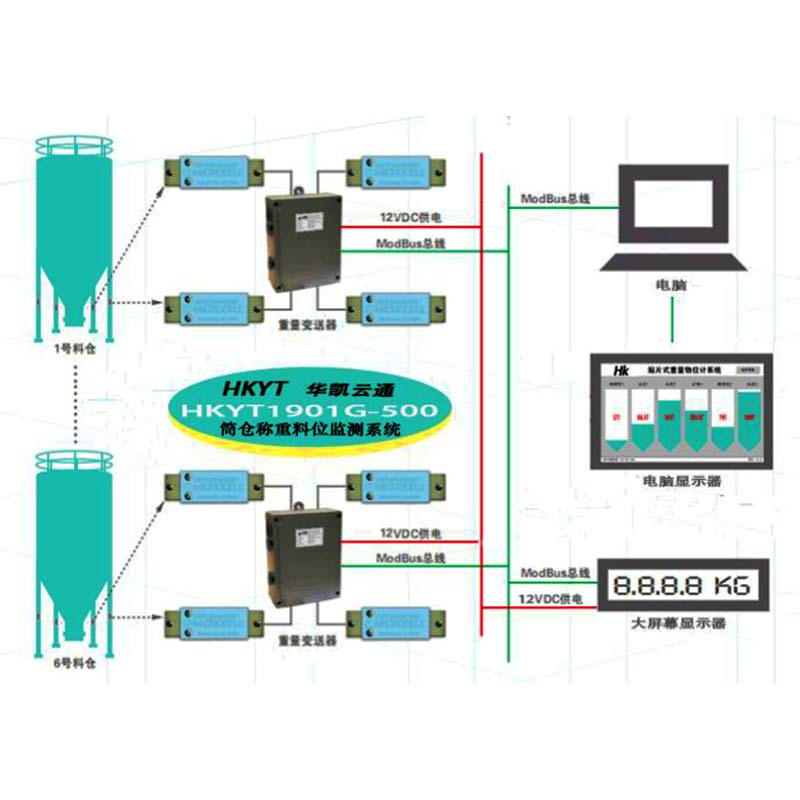

Silo Bulk Material Weighing and Monitoring System

Product origin :China

Revolutionize your silo management with our advanced Bolted Cement Silo Bulk Material Weighing System, leveraging cutting-edge German micro-strain sensor technology and IoT solutions for end-to-end digitalized storage management. Unlike traditional level sensors prone to mechanical failures, our system uses multi-point weight monitoring to deliver precise, real-time data on bulk material storage, ensuring safety, efficiency, and operational control. With a minimum precision error of ≤1% (and ≤3% under normal conditions), it eliminates risks of understocking, overfilling, and manual inspection hazards while integrating seamlessly with ERP and industrial software for smart, data-driven decision-making. Designed for easy installation on silo support legs, this system transforms your silo into an intelligent weighing unit, ideal for industries relying on bulk material storage.

Core Features of Bolted Cement Silo Bulk Material Weighing Systems

1. Enhanced Safety & Reliability

- Eliminates Manual Risks: Replaces dangerous manual climbing or silo knocking with automated weight monitoring, reducing personnel safety hazards.

- Multi-Point Monitoring: Unlike single-point traditional level sensors (e.g., rotary paddle or radar), our system uses 4 strain sensors per silo for balanced, reliable measurements, minimizing mechanical failure risks.

2. Precision & Stability

- Advanced Technology: Equipped with voltage stabilization, anti-interference, and temperature compensation modules to ensure stable input/output and consistent accuracy: ≤1% error under ideal conditions, ≤3% in normal operations.

- Prevent Operational Disruptions: Real-time weight data avoids costly issues like silo overloading or material shortages.

3. Efficiency & Convenience

- Rapid Data Management: Generates Excel reports in minutes for easy inventory tracking and analysis, streamlining administrative workflows.

- User-Friendly Interface: Intuitive software and quick setup reduce manual data entry and monitoring efforts.

4. Intelligent Integration

- Seamless Connectivity: Supports dBus/ModBus protocols for integration with ERP systems, ash conveying systems, and other management software, enabling centralized control and real-time data synchronization.

- Remote Access Ready: Optional 5G mobile connectivity allows monitoring via smartphones, ensuring access to critical data anytime, anywhere.

System Components

Product Name & Model | Unit | Qty | Notes |

Micro-Strain Sensors & Connectors (HKYT-500) | Set | 4 | 4 sensors per silo for balanced weight measurement. |

Network Server (DR302) | Unit | 1 | 1 per production line for data aggregation. |

Host Terminal (HKYT-ZD1) | Unit | 1 | 1 per silo for local data processing. |

Switching Power Supply (LM100-20B, 24VDC) | Unit | 1 | 1 per production line. |

4-Core Cable | Meter | 30 | Cabling for sensor connectivity. |

Electrical Control Box (with circuit breakers) | Unit | 1 | 1 per production line. |

Monitoring Software | Set | 1 | 1 per customer for full data visualization. |

Optional Upgrades

1. Single Silo Display & Alarm Light

Enhance local monitoring with real-time visual feedback and instant alerts for abnormal weight levels:

Product | Unit | Qty | Notes |

Display Terminal (HKYT-ZD2) | Unit | 1 | Real-time weight display (e.g., "8.8.8.8KG") for quick local status checks. |

24V Alarm Light | Unit | 1 | Flashing visual alerts for over/under-weight conditions to prevent risks. |

2-Core Cable | Meter | 30 | Cabling for connecting the display terminal and alarm light to the system. |

2. LED Screen Displays

Choose between silo-specific or production-line-wide visibility for clear, dynamic data presentation:

Single Silo (P10 LED Screen)

Product | Unit | Qty | Notes |

P10 LED Screen | Unit | 1 | High-brightness screen for per-silo display. |

2-Core Cable | Meter | 30 | Cabling for local installation, ensuring clear visibility at the silo site. |

Production Line (P5 LED Screen, 1000×500mm)

Product | Unit | Qty | Notes |

P5 LED Screen (1000×500mm) | Unit | 1 | Large shared screen for multi-silo monitoring. |

2-Core Cable | Meter | 50 | Extended cabling for centralized display installation across the production line. |

3. Mobile Monitoring (5G)

Enable remote access and real-time updates via smartphones for ultimate flexibility:

Product | Unit | Qty | Notes |

5G Mobile Gateway (DR502) | Unit | 1 | 5G-enabled gateway for seamless smartphone connectivity and remote data access. |

RS485 Signal Isolator | Unit | 1 | Ensures stable, interference-free signal transmission for reliable mobile monitoring. |

Each upgrade is designed to complement the basic system, offering scalable solutions for improved visibility, alerting, and remote control—tailored to your operational needs.

Installation & Operation

1. Simple Bolt-On Installation:

- Mount patch-type sensors (SHRYT-600) on silo support legs using bolts—no welding required.

2. Key Installation Tips:

- Install sensors only after the mounting base is fully cooled.

- Tighten 4 sensor bolts evenly to 22–23 Nm torque to avoid deformation.

- Verify correct wiring and secure connections to prevent data errors (check for loose terminals post-installation).

Technical Specifications

- Power Supply: 12VDC (for weight transmitters), 24VDC (system components).

- Communication: dBus/ModBus protocols for stable data transfer.

- Environment: Industrial-grade design with high resistance to electrical interference and temperature fluctuations.

- Accuracy: ≤1% (ideal conditions), ≤3% (normal operating conditions).

- Dimensions & Weight: Sensor size and system weight vary by configuration—contact us for detailed specs.

Applications

Perfect for industries such as cement, chemicals, food, mining, and construction, suitable for monitoring bulk materials like cement, fly ash, grains, and granular solids in silos, tanks, and hoppers.

Why Choose Our System?

- Future-Ready: Scalable configurations adapt to single silos or large production lines.

- Cost-Effective: Reduces labor costs, material waste, and downtime from operational errors.

- Trustworthy: German-engineered sensors ensure long-term reliability and precision.

Upgrade your bolted cement silo management today with a system that prioritizes safety, accuracy, and smart integration.

Contact us for custom solutions, pricing, and technical support!

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more