- Home

- >

- Products

- >

- Building Materials Machinery

- >

- Mobile Jaw Crusher

Mobile Jaw Crusher

Brand :CAFU

Product origin :China

Jaw crusher, as the main crushing equipment of stone crusher and rock crusher, is widely used for crushing construction waste, weathered stone, cobblestone, ore and concrete.

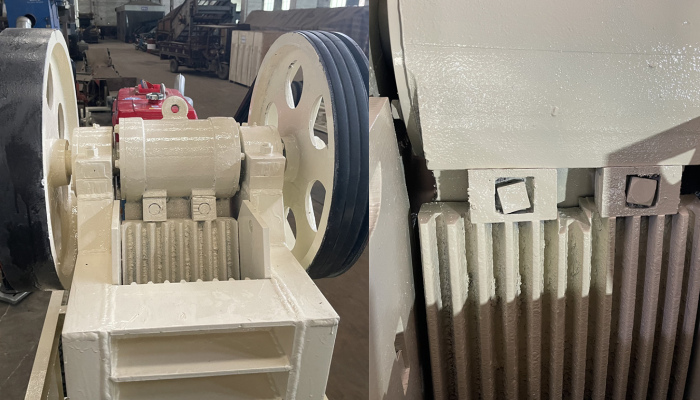

Mobile Jaw Crusher

Mobile Jaw Crusher, referred to as Jaw Crusher, has the features of large crushing ratio, even product size, simple structure, reliable operation, easy maintenance and economic operation cost. Jaw crusher is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other departments, crushing various materials with compressive strength not more than 320 MPa. Jaw crusher is made of high strength manganese steel, one-time moulding casting, which has the advantages of wear-resisting, compression-resisting, long life and so on. Jaw crusher is mainly suitable for crushing large, medium and small stones and corresponding objects.

1

Advanced components, well-made

The movable jaw is made of good materials and is durable. The jaw assembly is made of high quality cast steel parts and is driven by two large cast steel flywheels. In addition, the heavy duty eccentric shaft is made of forged billet, which makes the PE series jaw crusher work more reliably.

2

Reliable fit and high strength

The bearing housing adopts integral cast steel structure, the integral cast steel bearing housing can ensure the complete fit with the crusher frame, and also greatly enhance the radial strength of the bearing housing, while the split bearing housing does not have this advantage. Adopting finite element analysis technology, the crusher has higher strength.

3

Simple, safe and quick operation

The crushing chamber adopts symmetrical "V" shape structure, which makes the actual width of the feed opening consistent with the nominal width of the feed opening. The PE series jaw crusher is equipped with a wedge discharge opening adjustment device, which is simpler, safer and faster than the old-fashioned gasket adjustment.

4

Flexible combinations, on-demand customisation

Combined design with mobile rack, apron feeder, belt conveyor and vibrating screen can fully meet customers' functional requirements for small mobile crushing plant. Power options: can be equipped with motor or diesel power.

▌Mobile Jaw Crusher Mainframe Parameters (mobile frame according to customer requirements)

| Model | Inlet Size(mm) | Max. feed size(mm) | Discharge port size(mm) | Handling capacity(t/h) | Motor power(kw) |

| PE-150*250 | 150*250 | 125 | 10-40 | 1-3 | 4P 5.5 |

| PE-200*300 | 200*300 | 180 | 15-50 | 2-6 | 4P 7.5 |

| PE-200*350 | 200*350 | 180 | 18-70 | 3-10 | 4P 11 |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-21 | 6P 15 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-64 | 6P 30 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 6P 55 |

| PE-600*750 | 600*750 | 500 | 150-200 | 80-240 | 6P 55 |

▌Product details and packaging

As a source factory and advanced rock crusher OEM factory for many foreign trade customers, our small mobile jaw crusher has obvious cost advantage and stable product quality.

If you happen to have a need for small mobile stone crusher, please feel free to contact us for customized cost-effective rock crusher.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more