- Home

- >

- Products

- >

- Building Materials Machinery

- >

- Concrete Mixing Machine

Concrete Mixing Machine

Brand :Cafu

Product origin :China

The HZS25~HZS90 series developed and designed by CAFU, small concrete mixers are widely used in Southeast Asia, Africa and South America markets.

The mixing station series products are all independently produced and manufactured, including the mixing host, batching station, belt conveyor, equipment support, bolt-assembled steel silo (50-100T), metering system, and control system.

All small concrete mixing plants are pre-installed and manufactured in the factory. They are manufactured using precise CAD measurement and are matched with strict quality control standards. This enables customers to complete various installation and commissioning tasks according to our remote video guidance, reducing installation troubles caused by engineers' cross-border difficulties.

CAFU's years of experience in the construction of small concrete mixing plants in major foreign markets has enabled our engineers to better understand the actual needs of the local area, and we will provide customers with comprehensive and systematic product services.

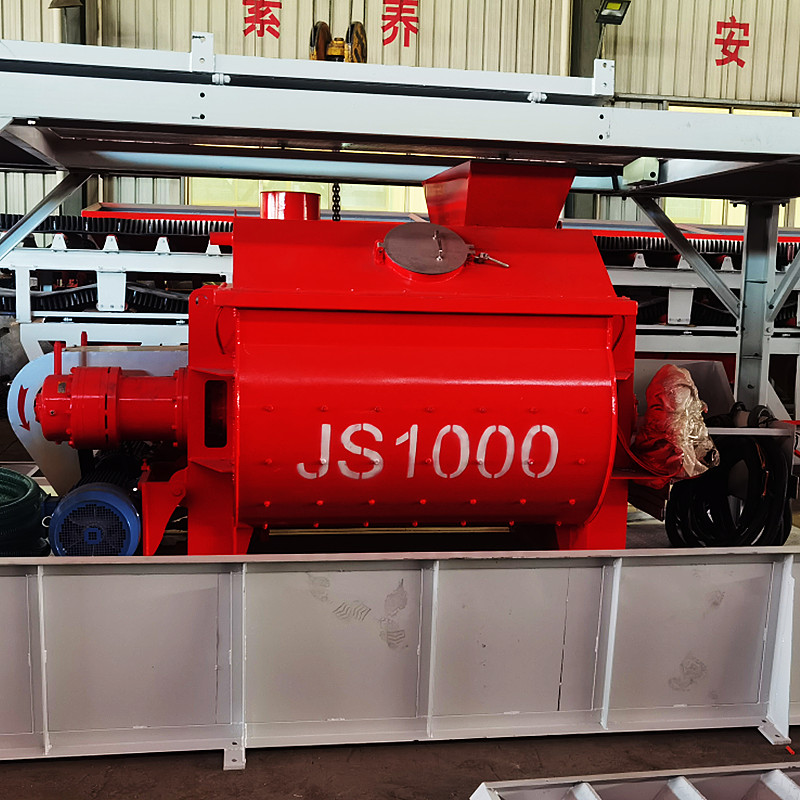

●JS series vertical mixer:

This machine is a two-horizontal-shaft forced concrete mixer, which is used in various medium and small prefabricated component factories and brick machines, highways, bridges, water conservancy, docks and other industrial and civil construction projects. It can mix hard concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortars. In addition to being used as a stand-alone machine, it can also be combined with a PL1200 batching unit to synthesize a simple mixing plant, and it can also be used as a supporting host for the HZS50 small concrete mixing plant.

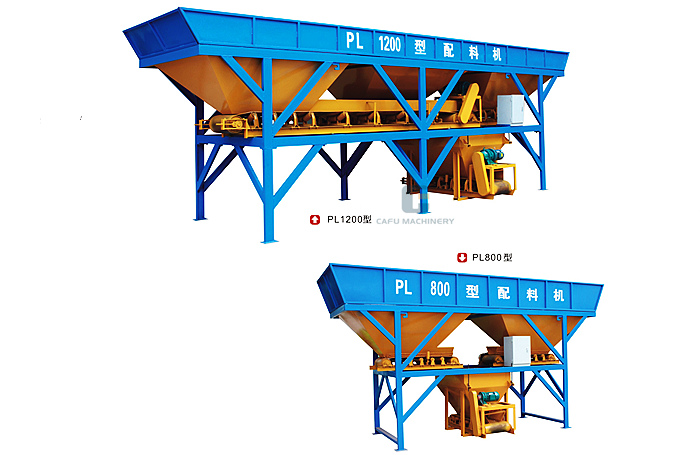

●PL series concrete batching machine:

The PL series concrete batching machine is a front desk automatic batching equipment used in conjunction with a concrete mixer. It can automatically complete the batching procedures of three kinds of aggregates such as sand and stone according to the concrete formula set by the user.

The PL series concrete batching machine is used in conjunction with the JS series concrete mixer to form a simple and small concrete mixing plant. It is an ideal equipment for producing high-quality concrete in various industrial and civil construction projects, small and medium-sized construction sites and prefabricated component factories.

●Vertical shaft rapid mixer

Planetary concrete mixer

The forced planetary concrete mixer realizes the uniform mixing of concrete through the compound motion of extrusion and turning driven by rotating planets and blades.

The mixing blade is designed as a parallelogram structure, which can be rotated 180° for repeated use to increase the service life. A special discharge scraper is designed according to the discharge speed to improve productivity.

The material in the trough moves smoothly and continuously, and the blade track covers the bottom of the entire trough after one cycle.

●HZS series concrete batching plant

| Model | HZS25 | HZS35 | HZS50 | HZS75 | HZS100 | |

| Theory productivity(m³/h) | 25 | 35 | 50 | 75 | 100 | |

Concrete mixer | Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixing power(kw) | 18.5 | 30 | 18.5×2 | 30×2 | 37×2 | |

Discharge volume (m³) | 0.5 | 0.75 | 1 | 1.5 | 2 | |

Max of aggregate (mm) | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Aggregate storage hopper(m³) | 3×4 | 3×4 | 3×6 | 3×8 | 4×20 | |

| Hoist motor(kw) | 5.5 | 7.5 | 18.5 | 22 | 30 | |

Weighing accuracy | Aggregate(kg) | 1200±2% | 1800±2% | 2400±2% | 3600±2% | 2×2400±2% |

| Cement(kg) | 300±1% | 500±1% | 500±1% | 800±1% | 1000±1% | |

| Fly ash(kg) | 150±1% | 200±1% | 300±1% | |||

| Water(kg) | 150±1% | 200±1% | 200±1% | 300±1% | 500±1% | |

| Additive(kg) | 20±1% | 20±1% | 30±1% | 30±1% | 40±1% | |

| Discharge height(m) | 3.85 | 3.85 | 3.85 | 3.85 | 3.85 | |

Total power(exclude silo and screw conveyor) | 40 | 55 | 75 | 105 | 135 | |

◆Warehouse inventory with complete accessories can quickly meet customers' purchasing needs.

◆Shipment scene of concrete batching plant:

Project case of concrete mixing station:

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more