- Home

- >

- News

- >

- Company news

- >

- Ton Bag Unpacking Stations in Powder Conveying System

Ton Bag Unpacking Stations in Powder Conveying System

Application of Ton Bag Unpacking Stations in Powder Conveying System

In the packaging of bulk materials, Ton Bag is often used for packaging to improve the turnover efficiency of bulk materials in the transport process.

The bulk materials loaded in Ton Bag are usually powder and granular solid materials. After being transported to the factory, these Ton Bag-packed bulk materials need to be unpacked and then conveyed to storage silos or other processes through pneumatic conveying systems.

However, in the process of unpacking Ton Bags, if proper Unpacking Stations are not used, dust or material spillage will often occur. Therefore, when designing the pneumatic conveying system, the use of Ton Bag Unpacking Stations specially designed for Ton Bag Unpacking and feeding the pneumatic conveying system can effectively avoid the dust pollution and spilling of bulk materials during the Ton Bag Unpacking process.

Ton Bag Unpacking Stations are usually designed according to the customer's site and the nature of the material. Generally applicable to the powder pneumatic conveying system of the unpacking station, our company will be designed into a fully enclosed type. Generally, Ton Bag Unpacking Stations consist of pulse dust collector, electric hoist, sealing chamber, pneumatic door, hopper, bag breaker, activation hopper, steel frame and control system. It is connected with Bin Pump through flexible connection. Its overall height is about 7m.

Usage process of Ton Bag Unpacking Stations.

1、0pen the pneumatic door, hang the ton bag on the Hang bracket, raise the electric hoist, and send the ton bag into the unpacking chamber.

2、Turn on the pulse dust collector, lower the electric hoist, and start unloading.

3、Manually raise and lower the electric hoist to empty the powder particles in the ton bag.

4、0pen the pneumatic door and check if the material inside the ton bag is clean.

5、After the material is cleaned, move the electric hoist out of the sealing chamber.

6、Close the pneumatic door and activate the pneumatic conveying system.

7. Wait for the alarm reminder of the pneumatic conveying system to start the next cycle.

8、The activation hopper is controlled by a pneumatic conveying system.

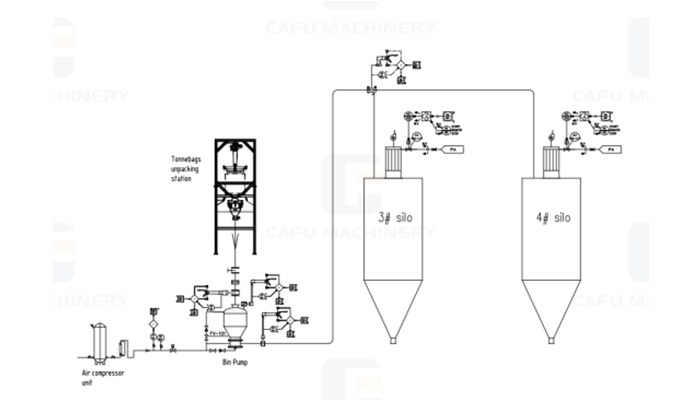

The above picture is a customised Ton Bag Unpacking Stations pneumatic conveying system for a European customer. The customer's original unpacking often produces material spills and dust pollution, so we designed this system for the customer, which will comprehensively improve the customer's existing problems.

Our pneumatic conveying system complete sets of equipment can meet CE-MD standards to meet the safe use requirements of all kinds of customers. Welcome your enquiry, we will provide free design for you.