- Home

- >

- News

- >

- Industry news

- >

- The Working Principle of Apron Feeder

The Working Principle of Apron Feeder

In a bulk ore processing line, the apron feeder is the front-end equipment that functions as the feed volume control for the line. A thorough understanding of the operating principles is essential to optimize a range of industrial processes.

The apron feeder is constructed with a series of metal pans or plates, which are connected in a specific configuration. These components are interconnected to form a continuous conveyor belt-like structure. The selection of appropriate materials for these pans, typically wear plate, is of paramount importance. The use of wear plate provides the requisite durability to withstand the substantial weight and abrasive nature of the materials being transported. To illustrate, in mining operations where ores are transferred, the wear pans are capable of withstanding the impact and abrasion caused by the rough texture of the ores.

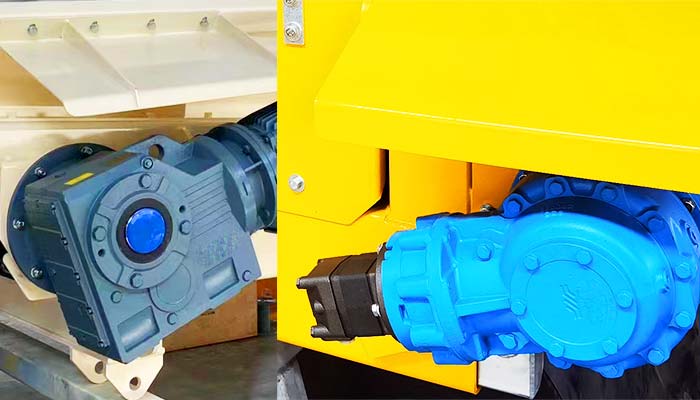

The drive mechanism of the apron feeder is typically composed of a motor and a reducer, which are integrated to facilitate the desired motion. The drive mechanism may be powered by electricity or hydraulics. In certain instances, the utilization of variable frequency motors facilitates a more exacting control of the bulk ore feed.

The apron feeder is equipped with a customized wear hopper. Based on the bucket capacity of the loader, a customized hopper is capable of storing bulk ore in a volume several times greater than that of the bucket capacity or an equivalent amount. The side walls of the hopper are usually lined with wear plates to withstand material abrasion. Thickened wear strips are installed on the sides close to the conveyor pan, where sliding wear is highly prone to take place.

In industries such as mining, quarrying, and power generation, apron feeders ensure a reliable and efficient process by providing a uniform and steady flow of material to downstream equipment. They are suitable for a wide range of applications, including bulk ore sorting lines, quarries, aggregate crushing, and sand plants. For further information about this product, please do not hesitate to contact CAFU. Our team is available to provide you with professional and comprehensive product services.