- Home

- >

- News

- >

- Company news

- >

- Roll Crusher Wear Shell (Roller Shell)

Roll Crusher Wear Shell (Roller Shell)

Since most Cement Plant Spares are cast in alloy form, in daily use and later repair process, due to the defects of process materials and parent materials, it is easy to cause abnormal damages such as cracking of grinding rolls and discs, which can not be repaired again. After years of exploration and accumulation in the wear-resistant material industry, our company can provide all models of vertical mills and coal mills with brand-new cement plant spare parts such as grinding rolls, roller sleeves and grinding discs with quality and cost advantages.

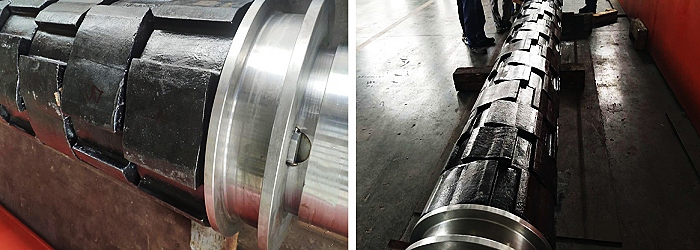

CAFU machinery for cement plant customers standing roll crusher wear shell (crushing shell), used in roll crusher, installed in the two sections of the cooler articulation. The crushing rolls of roll crusher are driven by gear motor. The material of wear sleeve is 1Cr13, which has good hardenability, high hardness, toughness and good corrosion resistance, heat strength and cold deformation performance, and good shock absorption. It is a Cement Plant Spares with excellent performance.

◇Performance Parameters:

Yield strength (Mpa): ≥980

Tensile strength (Mpa): ≥1200

Elongation (%): ≥8

Segment shrinkage (%): ≥15

Hardness (HB): 355-400

◇Metallographic organization: slaty martensite + a small amount of δ ferrite + trace residual austenite

1. Slab martensite is an excellent organization with high strength, high hardness and a certain plastic toughness.

2. As the C content of 1Cr13 material is ≤0.15, there will be a certain amount of δ-ferrite in the microstructure, resulting in low mechanical properties and hardness of the steel. By adjusting the alloying elements, the content of δ ferrite is reduced, so that the strength and hardness can be guaranteed.

3. When the residual austenite and brittle hard martensite coexist, it has good damping effect, and under the action of alternating stress, it can improve the fatigue strength of steel.

Different cement plant spare parts have different production process, for more product description of cement plant parts, please consult CAFU Company.