- Home

- >

- News

- >

- Industry news

- >

- Heavy Duty Apron Feeder In An Aggregate Processing Plant

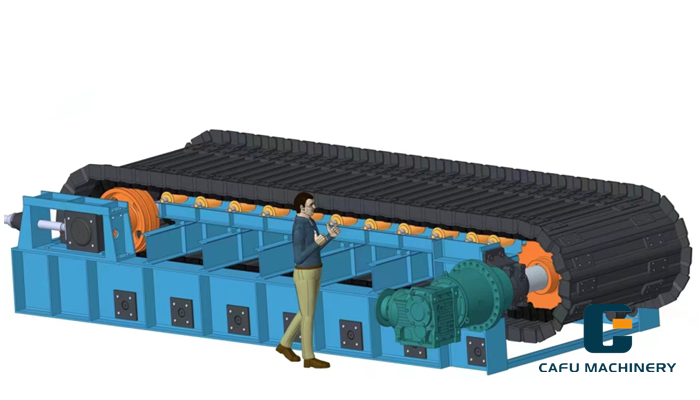

Heavy Duty Apron Feeder In An Aggregate Processing Plant

In an aggregate processing plant, a heavy-duty apron feeder plays a crucial role. It is designed to handle large volumes of various aggregates, such as stones, gravel, and ores.

The heavy-duty construction of the apron feeder allows it to withstand the harsh conditions and heavy loads typically encountered in aggregate processing. It consists of a series of overlapping metal plates or aprons that move continuously to transport the aggregates along a specific path.

The main functions of the heavy-duty apron feeder include:

- Consistent feeding: It ensures a steady supply of aggregates to downstream processes, maintaining a smooth operation.

- Withstand heavy loads: It can handle large quantities of heavy materials without significant wear and tear.

- Control the feed rate: By adjusting the speed of the aprons, the feed rate can be controlled to match the requirements of the subsequent processing stages.

This type of feeder is essential for efficient aggregate handling and processing, helping to optimize the overall productivity and performance of the plant. For example, in a quarry, a heavy-duty apron feeder can continuously supply crushed stones to crushers or conveyors for further processing. It also helps to prevent clogging and ensures a continuous flow of materials. In summary, the heavy-duty apron feeder is a vital component in an aggregate processing plant, enabling reliable and efficient handling of aggregates for various applications.