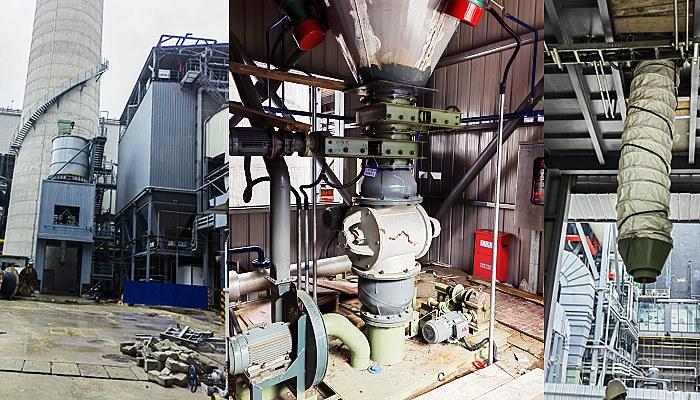

Pneumatic ash removal system

Coal gas power station (dry desulphurization) pneumatic ash removal system & ash storage accessory equipment project

The scale of the new power plant is:

3×430t/h high-efficiency supercritical coal gas boiler;

3×145MW high-efficiency supercritical intermediate reheat condensing steam turbine;

The power plant is synchronized with the construction of boiler flue gas desulphurization and dust removal system. The process of this project adopts baking soda dry desulfurization and dust removal integrated technology.

This pneumatic conveying system uses dense phase conveying and its main design parameters are:

1. There are 12 ash hoppers under the dust collector, and the ash volume of 12 ash hoppers is evenly distributed. The handling capacity of the ash removal system is designed according to 200% of the ash removal capacity.

2. The horizontal conveying distance between the dust collector and the ash storage is about 120 meters, the conveying height difference is about 25 meters, and the number of elbows is 9.

The ash conveying pipe section is made of carbon steel pipe and the elbows are made of ceramic lined wear-resistant elbows. At the same time, the system is installed with a device to eliminate pipe blockage.

For information and design of pneumatic conveying system of ash powder for boiler coal gas combustion system in thermal power plant, please contact CAFU.