- Home

- >

- News

- >

- Industry news

- >

- How To Choose the Best Apron Feeder for Mining?

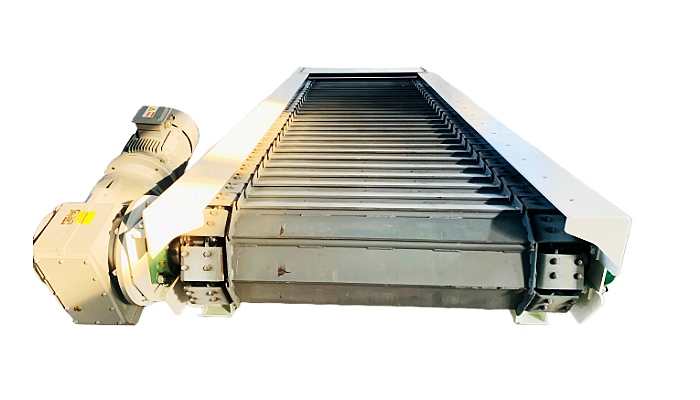

How To Choose the Best Apron Feeder for Mining?

When selecting an apron feeder for mining, the following aspects can be considered:

Capacity: Ensure that the conveyor capacity of the apron feeder can meet the material handling volume according to the output requirements of the mining operation. For example, large mines may require a high capacity feeder to accommodate large production. Therefore, it is necessary to select a high-capacity apron feeder to feed material to the crusher.

Material characteristics: Consider the particle size, hardness, corrosiveness, stickiness, etc. of the materials. For materials with high hardness, the material and strength of the apron should be sufficient; for sticky materials, a special design of the apron may be required to prevent adhesion. At the same time, it is also necessary to ensure that the hopper lining is wear-resistant enough to reduce impact wear from the materials.

Working environment: Includes temperature, humidity, dust, and other conditions. In harsh environment, equipment with high protection level, wear resistance and corrosion resistance must be selected.

Chain plate structure and quality: Examine the strength, wear resistance and tensile strength of the chain plate. High-quality chain plates can prolong the service life of the equipment and reduce the number of maintenance operations. Chain plates made of high quality wear-resistant alloys can be selected.

Drive System: A strong and stable drive system is the key to ensuring the normal operation of the feeder. It is necessary to select a motor, reducer, etc. with appropriate power and reliable performance.

Installation and Maintenance Convenience: Facilitate installation and subsequent maintenance. Apron feeders with reasonable structure design and easy disassembly and maintenance are more popular.